Are There Any Industry-Specific Adaptations of Worm Grinding Machines?

Worm grinding machines have become an integral part of many industries due to their adaptability and efficiency. These machines, specifically designed for the manufacturing of worm gear sets, have found applications in diverse industries, including automotive, aerospace, and machinery. The industry-specific adaptations of worm grinding machines are primarily due to the diverse requirements of these industries in terms of precision, speed, and efficiency.

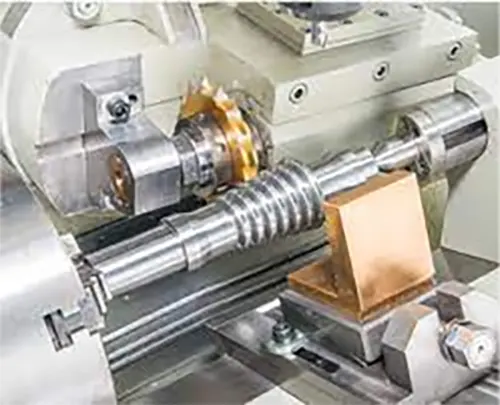

Structure of the Worm Thread Grinding Machine

Before delving into the industry-specific adaptations, it is crucial to understand the structure of the worm thread grinding machine. The structure constitutes the following components:

- Main Spindle System: This component is responsible for rotating the worm gear workpiece.

- Grinding Head System: This is the component used for grinding the worm thread.

- Feed System: This component controls the relative motion between the worm gear workpiece and the grinding head.

- Lubrication System: This component lubricates the parts of the grinding machine.

- Control System: This component controls the processing of the worm thread grinding machine.

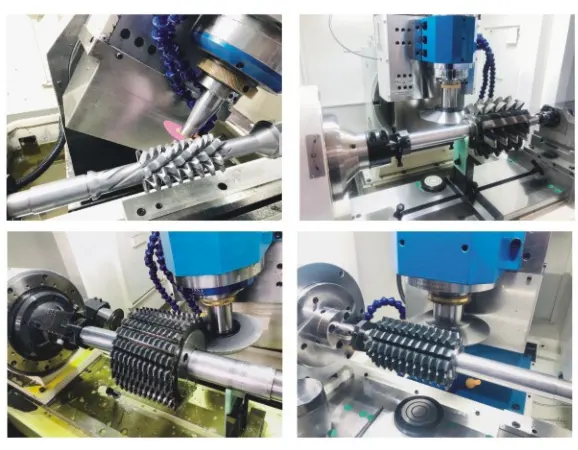

Working Principle of the Worm Grinding Machine

The working principle of the worm thread grinding machine involves the use of grinding grains on the grinding head to cut the surface of the worm, thereby achieving the required worm thread. The precision of the worm thread grinding machine depends on the structural design of the grinding machine, the quality of the grinding head, and the processing technology. The working principle involves the following steps:

- Rotation: The main spindle system rotates the worm gear workpiece.

- Grinding: The grinding head system grinds the worm thread of the rotating workpiece.

- Feeding: The feed system controls the relative motion between the workpiece and the grinding head.

- Lubrication: The lubrication system ensures smooth operation by lubricating the machine parts.

- Control: The control system manages the entire process, ensuring precision and efficiency.

Applications of the Worm Thread Grinding Machine

The worm thread grinding machine is primarily used in the manufacturing of worm gear transmission devices and reducers. These are common transmission devices with high transmission ratios, high efficiency, and low noise. They are widely used in various industries such as machinery, metallurgy, chemical, and construction. The specific applications include:

- Manufacturing worm gears for transmission devices: The quality of the worm thread directly affects the performance of the transmission device. The worm thread grinding machine can process worm threads of various precision requirements, meeting the usage requirements of the transmission device.

- Manufacturing worm gears for reducers: The quality of the worm thread also directly affects the performance of the reducer. The worm thread grinding machine can process worm threads of various precision requirements, meeting the usage requirements of the reducer.

- Manufacturing other parts requiring worm threads: Worm threads are also used in the manufacture of other parts, such as worm pumps, worm oil pumps, worm elevators, etc. The worm thread grinding machine can process worm threads of various precision requirements, meeting the usage requirements of these parts.

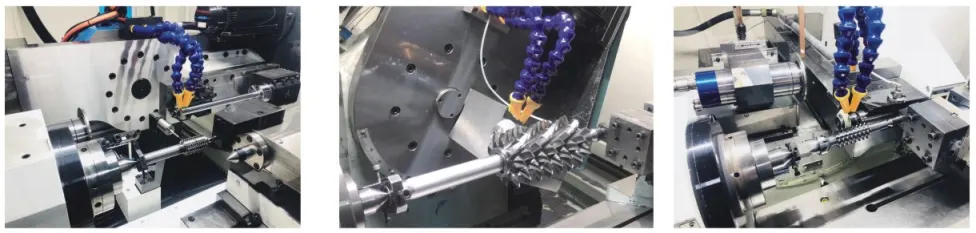

Why Choose Our Worm Grinding Machines?

As a professional manufacturer of CNC machine tools and gear hobbing tools, we pride ourselves on our experienced team of engineers and operators. We ensure each product meets the needs of our customers through our computer-optimized design, full CNC machining technology, and perfect quality control system (ISO9001 certified).

Furthermore, our excellent pre and post-sale service teams, intellectual property rights, and numerous patented technologies set us apart. Our high-efficiency and high-precision performance worm grinding machines, along with our self-developed software and competitive pricing, have made us a favorite among users.

We encourage you to explore our worm grinding machines and assure you of our commitment to excellent quality, advantageous price, effective supply, and outstanding service. Our hob and machine tool products are sold globally, and we look forward to having you as part of our worldwide customer base.