Are There Any Limitations to the Size of Gears That Can Be Processed with a Worm Grinding Machine?

A worm grinding machine is a powerful tool used to create high precision worm gears. While it can handle a wide range of gear sizes, it does have certain limitations. The size of the gear that a worm grinding machine can process is largely dependent on the size and capabilities of the machine itself. Larger gears require larger machines with greater capacity. However, with the advanced technology and precise control systems available today, worm grinding machines can handle most gear sizes efficiently and effectively.

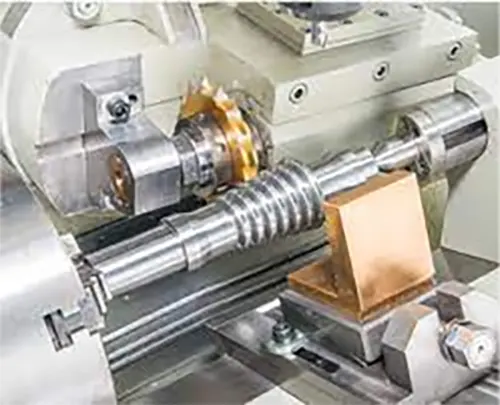

Structure of the Worm Thread Grinding Machine

A worm thread grinding machine is composed of five main systems:

- Main Spindle System: This system is used to rotate the worm gear workpiece.

- Grinding Head System: This system is used for grinding the worm gear threads.

- Feed System: This system controls the relative movement between the worm gear workpiece and the grinding head.

- Lubrication System: This system lubricates the components of the grinding machine.

- Control System: This system controls the machining process of the worm thread grinding machine.

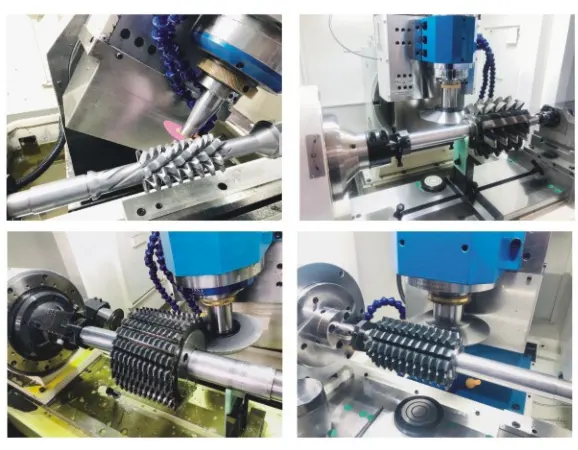

Processing Principle of the Worm Grinding Machine

The processing principle of the worm thread grinding machine involves the use of the grains on the grinding head to cut the surface of the worm gear to achieve the desired worm gear threads. The precision of the machining process depends on factors such as the structural design of the machine, the quality of the grinding head, and the machining process itself.

Applications of the Worm Thread Grinding Machine

Worm thread grinding machines are primarily used in the manufacturing of worm gear transmission devices and reducers. These devices are common transmission devices with advantages such as a high transmission ratio, high efficiency, and low noise. They are widely used in industries such as machinery, metallurgy, chemical, and construction.

Specific applications of worm thread grinding machines include:

- Manufacturing worm gears for worm gear transmission devices.

- Manufacturing worm gears for reducers.

- Manufacturing other parts that require worm gear threads, such as worm gear pumps, worm gear oil pumps, worm gear elevators, and more.

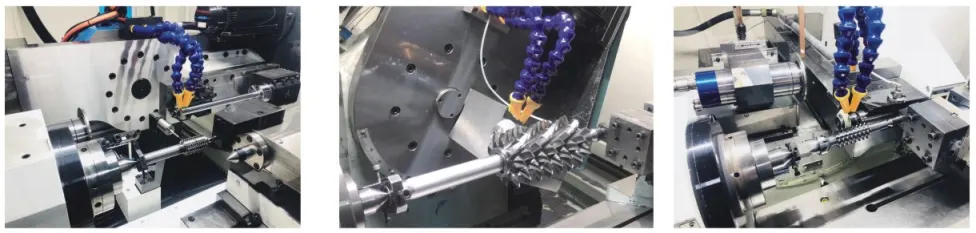

Why Choose Our Worm Grinding Machines

We are a professional manufacturer of CNC machine tools and gear hobbing tools. Our team of experienced engineers and operators, along with our excellent pre and post-sales service team, ensures that our products meet your requirements. Our worm grinding machines are high efficiency and high precision, featuring all self-developed software and offering high cost-effectiveness. We adhere to "excellent quality, advantageous price, effective supply, excellent service", selling our hob and machine tool products all over the world. We encourage you to explore our worm grinding machines and contact us for purchases.