The Impact of Temperature Control on Worm Grinding Machine Performance

Temperature control plays a significant role in the performance of a worm grinding machine. A well-regulated temperature ensures the precision of the grinding process, preventing thermal deformation of the machine parts. This, in turn, results in high-quality manufacturing of worm gears with accurate geometrical parameters and surface quality.

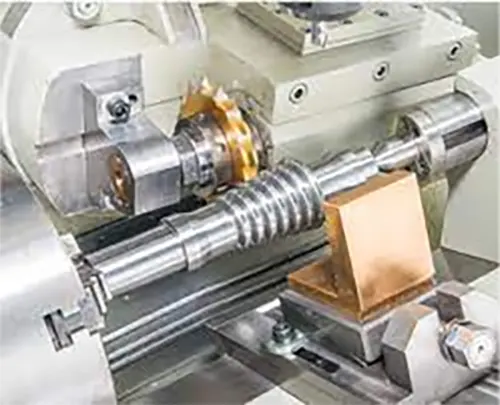

Structure of a Worm Thread Grinding Machine

The worm thread grinding machine is composed of five essential systems:

-

Main Spindle System:

This system rotates the worm workpiece.

-

Grinding Head System:

This system grinds the worm thread.

-

Feeding System:

This system controls the relative motion between the worm workpiece and the grinding head.

-

Lubrication System:

This system lubricates the machine components.

-

Control System:

This system controls the entire process of the worm thread grinding machine.

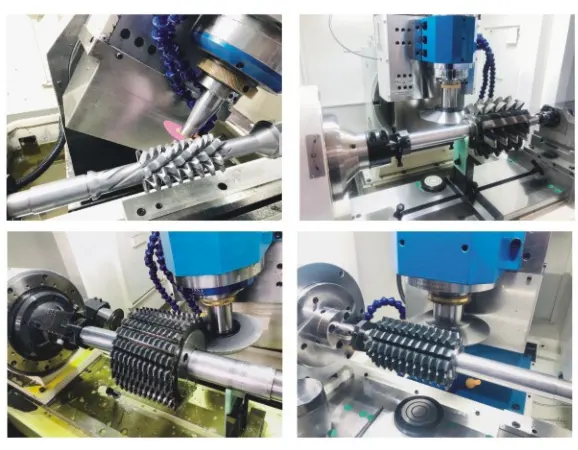

Working Principle of a Worm Grinding Machine

The worm grinding machine operates by utilizing the grinding grains on the grinding head to cut the surface of the worm, resulting in the desired worm thread. The precision of the grinding process depends on factors such as machine structure design, grinding head quality, and machining process.

Applications of a Worm Thread Grinding Machine

The worm thread grinding machine is primarily used in the manufacturing of worm gear transmission devices and reducers, which are integral in various industries like machinery, metallurgy, chemical, and construction. The specific applications include:

-

Manufacturing Worm Gears:

The quality of worm gears directly affects the performance of worm gear transmission devices. The worm thread grinding machine can manufacture worm threads of various precision requirements.

-

Manufacturing Reducer Worm Gears:

The worm gears in reducers are crucial as their quality directly affects the performance of the reducers. The worm thread grinding machine can manufacture worm threads of various precision requirements.

-

Manufacturing Other Worm Thread Parts:

Other parts such as worm gear pumps, worm oil pumps, and worm lifts also require worm threads. The worm thread grinding machine can manufacture worm threads of various precision requirements for these parts.

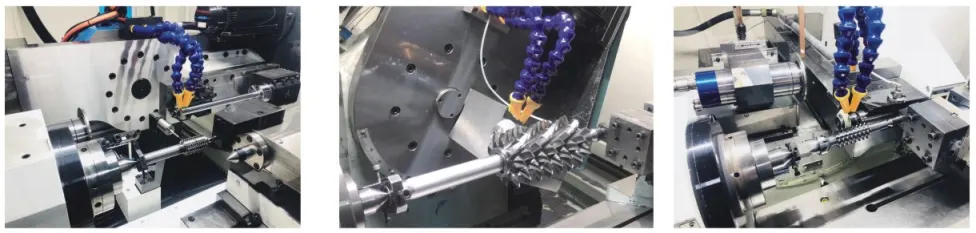

Our Worm Grinding Machine

We are a leading manufacturer of CNC machine tools and gear hobbing tools. Our team of experienced engineers and operators, along with our top-notch pre and post-sales service, ensure that we deliver the highest quality products to our clients. Our worm grinding machine, with its high efficiency, precision performance, and cost-effective features, is highly acclaimed by users worldwide. We invite you to explore our product and get in touch with us for your requirements. We assure you of outstanding quality, competitive pricing, and exceptional service.