How Does the Accuracy of Worm Grinding Machines Compare to Other Grinding Methods?

Worm grinding machines have been engineered to deliver exceptional precision compared to other grinding methods. This precision is owed to several factors such as the machine's structural design, the quality of the grinding head, and the machining process. This article will delve deeper into the design, working principle, and applications of worm grinding machines, and why they are the ultimate choice for your grinding needs.

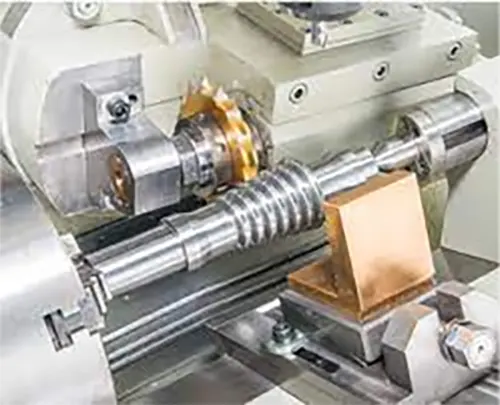

Structure of the Worm Thread Grinding Machine

The worm grinding machine comprises of:

-

Spindle System:

This component is used for rotating the worm workpiece.

-

Grinding Head System:

This part grinds the threads on the worm.

-

Feed System:

This system controls the relative movement between the worm workpiece and the grinding head.

-

Lubrication System:

This part lubricates the various components of the grinding machine.

-

Control System:

This system controls the process of grinding the worm threads.

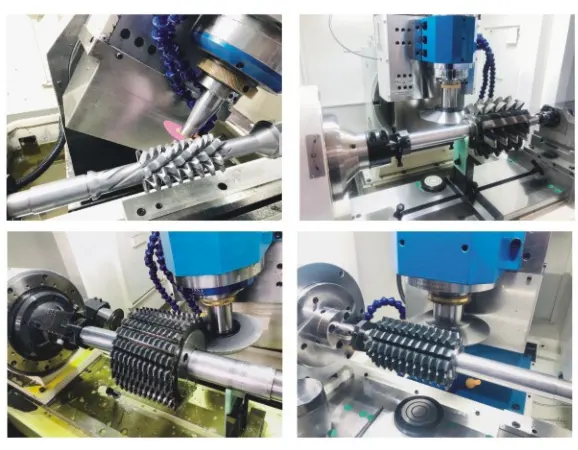

Working Principle of the Worm Grinding Machine

The worm thread grinding machine operates by using the grinding grains on the grinding head to cut the surface of the worm, thereby achieving the desired worm threads. The accuracy of the machining process depends on:

-

Structural Design:

A robust and efficient design ensures that the machine can handle the high precision required in worm grinding.

-

Quality of the Grinding Head:

A high-quality grinding head ensures consistency and accuracy during the grinding process.

-

Machining Process:

The process of machining, including the speed and feed rate, greatly impacts the final accuracy of the worm threads.

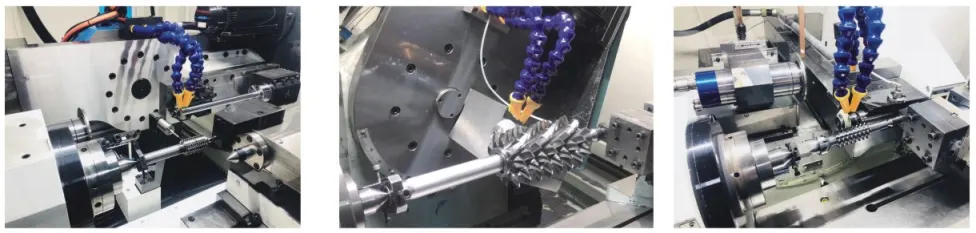

Applications of the Worm Thread Grinding Machine

Worm thread grinding machines are primarily used in the manufacturing of worm drive devices and gear reducers, among others. The specific applications include:

-

Manufacturing Worms for Worm Drive Devices:

The quality of the worm threads directly impacts the performance of the worm drive devices.

-

Manufacturing Worms for Gear Reducers:

The quality of the worm threads also significantly affects the performance of gear reducers.

-

Manufacturing Other Components:

Worm threads are also used to manufacture other components like worm pumps, worm oil pumps, worm lifts, etc. The worm thread grinding machine can machine worm threads to various precision requirements, meeting the needs of these components.

Why Choose Our Worm Grinding Machine?

We are a leading manufacturer of CNC machine tools and gear hobbing tools, boasting a team of engineers with vast experience in gear hobbing and CNC equipment manufacturing. We are committed to delivering excellence in product quality, competitive pricing, efficient supply, and stellar service. Our worm grinding machines are designed for high efficiency and precision, and they come with self-developed software, making them a favorite among users globally. We strongly encourage you to explore this product and contact us for purchase. You are guaranteed to receive a product that meets your needs from a manufacturer that prioritizes your satisfaction.