How to Ensure Consistency in Output When Using a Worm Grinding Machine?

When using a worm grinding machine, ensuring consistency in output is crucial. This is achieved by maintaining a stable operating environment, using quality grinding wheels, employing correct grinding techniques, and performing regular machine maintenance. These factors collectively ensure the machine operates at its peak efficiency and delivers consistent results.

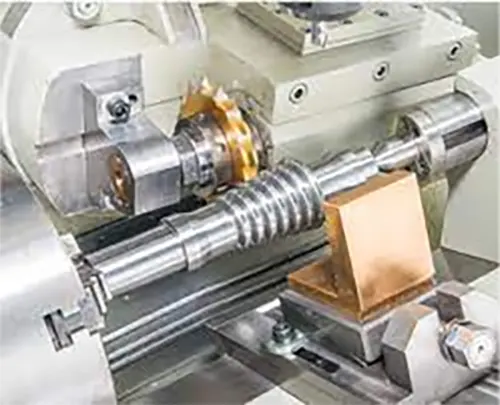

Structure of a Worm Thread Grinding Machine

A worm thread grinding machine consists of several key components, each playing a critical role in its operation. These include the main spindle system, grinding head system, feed system, lubrication system, and control system.

Main Spindle System

The main spindle system is responsible for rotating the worm gear workpiece. It ensures smooth rotation for accurate grinding.

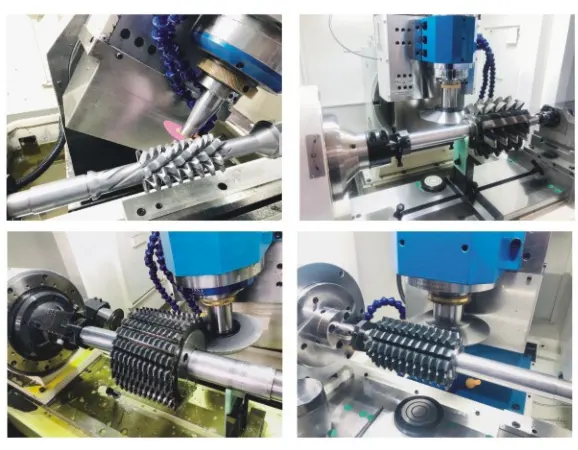

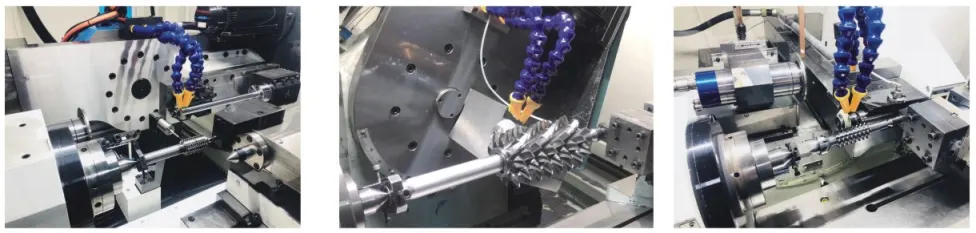

Grinding Head System

The grinding head system holds the grinding wheel in place. It grinds the worm gear threads to the required specifications.

Feed System

The feed system controls the relative motion between the worm gear workpiece and the grinding head. It ensures the correct grinding speed and feed rate for optimal grinding results.

Lubrication System

The lubrication system keeps all the machine components well-lubricated, reducing friction and preventing wear and tear.

Control System

The control system manages the entire grinding process. It controls the machine's operations and ensures precision and accuracy in the grinding process.

Working Principle of Worm Grinding Machine

The working principle of a worm grinding machine involves the use of grinding grains on the grinding head to cut the worm gear surface, thereby obtaining the required worm gear threads. The precision of the grinding process depends on the design of the machine, the quality of the grinding head, and the grinding process.

Applications of Worm Thread Grinding Machine

The worm thread grinding machine is primarily used in the manufacturing of worm gear drive devices and reducers. These are commonly found in industries such as machinery, metallurgy, chemical, and construction.

Manufacturing Worm Gears for Drive Devices

The quality of worm gear threads directly impacts the performance of the drive device. The worm thread grinding machine can process worm gear threads to meet various precision requirements, satisfying the use requirements of drive devices.

Manufacturing Worm Gears for Reducers

Similarly, the quality of worm gear threads affects the performance of reducers. The worm thread grinding machine can process worm gear threads to meet various precision requirements, satisfying the use requirements of reducers.

Manufacturing Other Worm Gear Threaded Parts

The worm thread grinding machine can also process worm gear threads for other parts such as worm gear pumps, worm gear oil pumps, worm gear lifts, and more, meeting their use requirements.

About Us

We are a professional manufacturer of CNC machine tools and gear hobbing tools. Our annual machine tool production capacity is about 80 sets, covering a wide range of tool industry machines. Our products are characterized by high efficiency, high precision performance, and cost-effectiveness, making them a favorite among users. We adhere to the principles of excellent quality, advantageous prices, effective supply, and excellent service.

We encourage you to explore our products and contact us for purchases. We assure you of our best services at all times and look forward to serving your needs with our high-quality products and competitive prices.