Setting up and Calibrating a Worm Grinding Machine

Worm grinding machines are highly specialized pieces of equipment used for the machining of precise worm gear threads. Proper setup and calibration are crucial to achieving the optimal performance and precision. The setup process involves adjusting the main spindle, grinding head, feed system, lubrication and control systems to ensure the machine operates smoothly and accurately. Calibration ensures that the machine’s settings align with the specific requirements of the task at hand.

Structure of a Worm Thread Grinding Machine

The worm thread grinding machine consists of several key systems that work in harmony to deliver precise and efficient grinding operations.

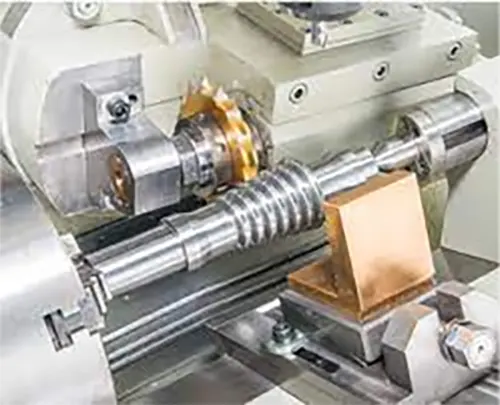

Main Spindle System

The main spindle system is responsible for rotating the worm gear workpiece. It needs to be set up to rotate at the correct speed and direction for the specific task.

Grinding Head System

The grinding head system houses the grinding wheel that shapes the worm gear threads. This system must be set at the right angle and position relative to the workpiece.

Feed System

The feed system controls the relative movement between the workpiece and the grinding head. It needs to be calibrated to ensure the correct feed rate and direction.

Lubrication System

The lubrication system provides necessary lubrication to the machine components. Proper lubrication reduces friction and heat, prolonging the life of the machine.

Control System

The control system manages the entire machining process. It needs to be programmed with the right parameters to guide the machine’s operation.

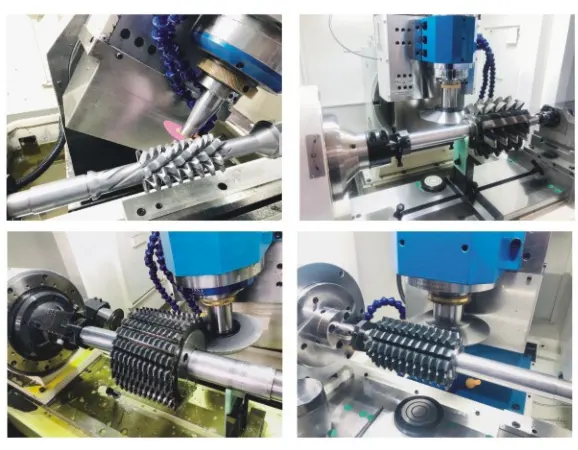

Working Principle of a Worm Grinding Machine

The worm grinding machine operates based on a simple yet effective principle. The grinding wheel’s abrasive particles cut into the surface of the worm gear, forming the desired thread shape. Several factors influence the machine’s precision:

Machine Structure Design

The machine's structural design plays a crucial role in ensuring its stability and accuracy during operation.

Quality of the Grinding Head

The quality of the grinding head directly affects the precision of the worm gear threads.

Machining Process

The machining process, including the feed rate, spindle speed, and grinding wheel selection, can significantly impact the final product’s quality.

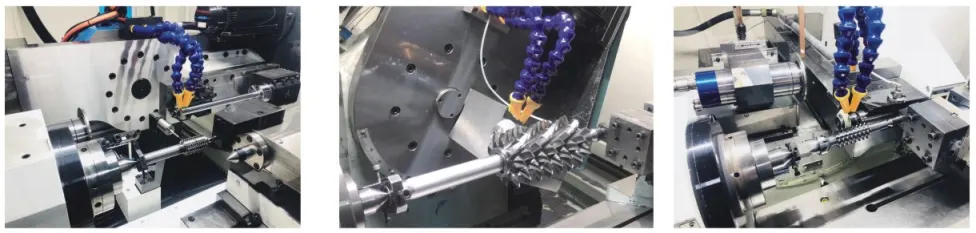

Applications of a Worm Thread Grinding Machine

Worm thread grinding machines are primarily used in manufacturing worm gear drive systems and reducers. These are common drive systems with high transmission ratios, efficiency, and low noise, widely used in various industries such as machinery, metallurgy, chemical, and construction. The machine's specific applications include:

Manufacturing Worm Gears for Drive Systems

Worm gears are key components of worm drive systems, and their quality directly affects the system's performance. The worm thread grinding machine can produce worm threads of various precision levels to meet the drive system's requirements.

Manufacturing Worm Gears for Reducers

Reducers, devices that decrease rotational speed, also heavily rely on worm gears. The worm thread grinding machine can produce worm threads of various precision levels to meet the reducer's requirements.

Manufacturing Other Worm Thread Parts

Worm threads are also used in other components such as worm gear pumps, worm gear oil pumps, and worm gear elevators. The worm thread grinding machine can produce worm threads of various precision levels to meet these components' requirements.

Why Choose Our Worm Grinding Machine?

We are a leading manufacturer of CNC machine tools and gear hobbing tools. Our company is backed by a team of seasoned engineers and operators with rich experience in gear hobbing and CNC equipment manufacturing. Our products are designed with computer optimization and produced using full CNC machining technology. We have a strict quality control system (ISO9001 certified) to ensure each product meets our customer's needs. Our worm grinding machine, with its high efficiency, precision performance, and cost-effective features, has been favored by users worldwide. We are committed to providing excellent quality, advantageous prices, effective supply, and superb service. We invite you to explore our products and contact us for any purchasing inquiries.