Description

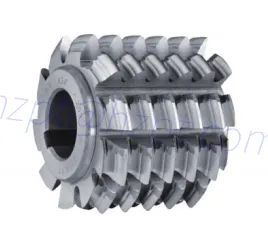

When it comes to the gear manufacturing industry, nothing is as crucial as having the right tools for the job. Circular-arc Gear Hobs are prime examples of such tools. They are fundamentally designed to cut and shape gears, bringing precision, accuracy, and efficiency to your processes. These hobs are widely accepted and utilized across various sectors such as automotive, aerospace, and machinery industries.

Discovering the Unique Features of Circular-arc Gear Hobs

These hobs are not just tools; they are a remarkable blend of innovative design and exceptional materials. Let's explore the key features that set Circular-arc Gear Hobs apart:

| Features | Description |

|---|---|

| Computer-optimized design | Designed using advanced computer-optimized techniques, ensuring optimal performance and efficiency. |

| Material Options | Available in high-speed steel and solid carbide materials, providing durability and longevity. |

| Variety of Sizes and Specifications | Available in a wide range of sizes, from M0.6 to M20, catering to various gear cutting needs. |

| Specialized Hob Types | In addition to standard hobs, there are specialized hobs available for specific applications such as synchronous pulleys, sprocket hobs, spline hobs, worm gear hobs, and disc milling cutters. |

| Cost-Performance Ratio | Offers excellent cost performance, providing high-quality gear cutting solutions at competitive prices. |

Maintaining Your Circular-arc Gear Hobs

To ensure the longevity and optimal performance of your Circular-arc Gear Hobs, regular maintenance is crucial. This involves cleaning, lubrication, and inspection of the hobs. Adhering to the manufacturer's guidelines for usage and storage is also recommended to extend the hob's lifespan.

Applications of Circular-arc Gear Hobs

Circular-arc Gear Hobs find applications in various sectors, such as:

- Automotive: For the production of gears for transmissions, engines, and differentials.

- Aerospace: In the manufacturing of gears for aircraft engines, landing gear systems, and other aerospace components.

- Machinery: In the production of gears for industrial machinery, power transmission systems, and heavy equipment.

Experience Excellence with HZPT

At HZPT, we are a leading manufacturer specializing in the production of gear hobbing tools and CNC machine tools. Our team of experienced engineers and operators are committed to delivering high-quality products and excellent service to our customers. We offer a comprehensive range of gear hobs, including high-speed steel hobs, solid carbide hobs, and various specialized hobs. We have a strong customer base, with over 1,500 customers continuously relying on our products and services.

Take Action Today

Experience the quality and performance that sets us apart by exploring our range of Circular-arc Gear Hobs. Contact us today to discuss your gear cutting needs and let us provide you with the best solutions. Trust HZPT for all your gear hobbing requirements!

Frequently Asked Questions

- What materials are used in the construction of Circular-arc Gear Hobs?

We use high-speed steel and solid carbide in the construction of these hobs, ensuring durability and longevity. - What sizes are available for Circular-arc Gear Hobs?

The hobs are available in a wide range of sizes, from M0.6 to M20, catering to various gear cutting needs. - Where can Circular-arc Gear Hobs be applied?

They find application in various sectors such as the automotive, aerospace, and machinery industries.