What Are the Energy Efficiency Considerations for Worm Grinding Machines?

Energy efficiency is a crucial factor in the operation of worm grinding machines. It pertains to how effectively the machine uses energy during operation. This encompasses the energy consumption of the main spindle system, grinding head system, feed system, lubrication system, and control system. An energy-efficient worm grinding machine optimizes power usage during operations, reducing unnecessary energy wastage and thus reducing operational costs. Moreover, it also contributes to sustainability efforts, a critical aspect in modern manufacturing processes.

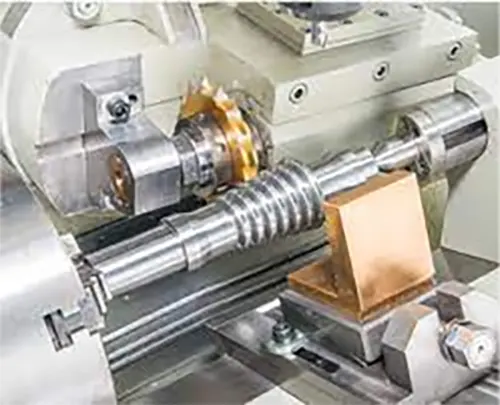

Structure of the Worm Grinding Machine

The worm grinding machine consists of five key components:

-

Main Spindle System

The main spindle system enables the rotation of the worm gear workpiece during grinding.

-

Grinding Head System

This component grinds the worm gear threads, shaping them into the desired form.

-

Feed System

The feed system controls the relative movement between the worm gear workpiece and the grinding head.

-

Lubrication System

This system lubricates the parts of the grinding machine, reducing friction and wear.

-

Control System

The control system manages the operations of the worm thread grinding machine during the manufacturing process.

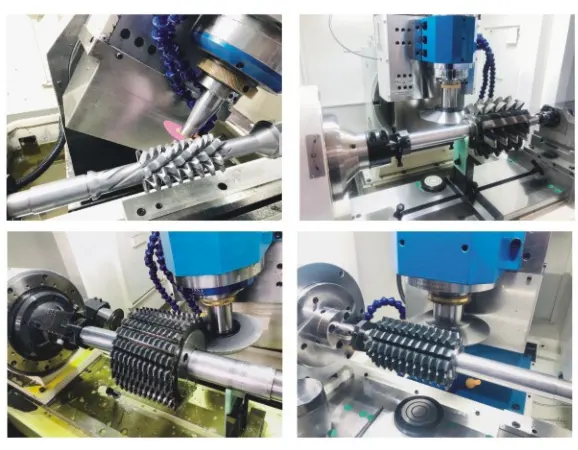

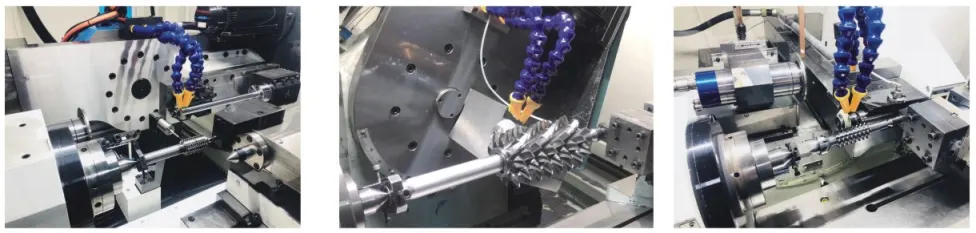

Working Principle of the Worm Grinding Machine

The worm grinding machine operates by using the grinding particles on the grinding head to cut the surface of the worm gear, resulting in the desired worm gear threads. The accuracy of the worm grinding machine is determined by its structural design, the quality of the grinding head, and the machining process.

Applications of the Worm Thread Grinding Machine

The worm thread grinding machine is primarily used in the manufacturing of worm gear drive systems and reducers, among others. The worm gear drive systems are common transmission devices, known for their high transmission ratio, efficiency, and low noise. They are widely used in machinery, metallurgy, chemical, and construction industries. Reducers are devices that lower rotational speed and are also extensively used in these industries.

The worm thread grinding machine is specifically used in the following applications:

-

Manufacturing Worm Gears in Drive Systems

The worm gear is a critical component in worm gear drive systems. The quality of the worm gear threads directly affects the performance of the drive system. The worm thread grinding machine can manufacture worm gear threads of various precision requirements, meeting the needs of worm gear drive systems.

-

Manufacturing Worm Gears in Reducers

Similar to drive systems, the worm gear in reducers is also a crucial component. The worm thread grinding machine can manufacture worm gear threads of various precision requirements, meeting the needs of reducers.

-

Manufacturing Other Parts Requiring Worm Gear Threads

Worm gear threads are also used in the manufacture of other parts such as worm gear pumps, worm gear oil pumps, and worm gear elevators. The worm thread grinding machine can meet the precision requirements of these parts.

Why Choose Our Products

We are a leading manufacturer of CNC machine tools and gear hobbing tools. Our company boasts a team of experienced engineers and operators, excellent pre-sales and after-sales service teams, and owns several patented technologies. Our product designs are optimized using computer-based designs, ensuring high efficiency and precision. We strongly encourage you to explore our range of products including the worm thread grinding machine and contact us to make a purchase. With our competitive prices, top-notch quality, and exceptional customer service, you are guaranteed to get value for your money.