What Role Does Wheel Selection Play in the Performance of a Worm Grinding Machine?

Wheel selection plays a vital role in the performance of a worm grinding machine. With the correct grinding wheel, the machine can achieve high precision and efficiency in machining worm threads. The right grinding wheel selection offers better surface quality for the worm threads, minimizing grinding burns or scratches. Therefore, it's crucial to choose the right grinding wheel based on the worm thread's material and the desired surface finish.

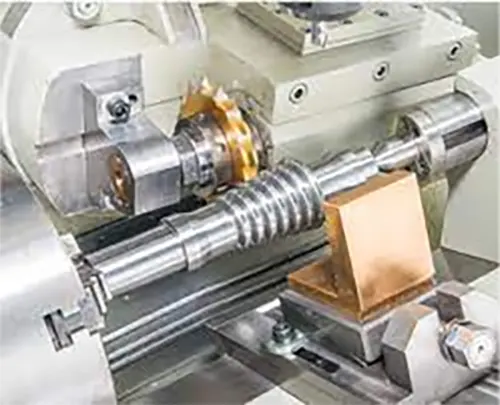

Structure of a Worm Thread Grinding Machine

The worm thread grinding machine consists of five main systems:

1. Spindle System

The spindle system is responsible for rotating the worm workpiece.

2. Grinding Head System

The grinding head system is the component that grinds the worm threads.

3. Feed System

The feed system controls the relative motion between the worm workpiece and the grinding head.

4. Lubrication System

The lubrication system lubricates the components of the grinding machine.

5. Control System

The control system manages the worm thread grinding machine's machining process.

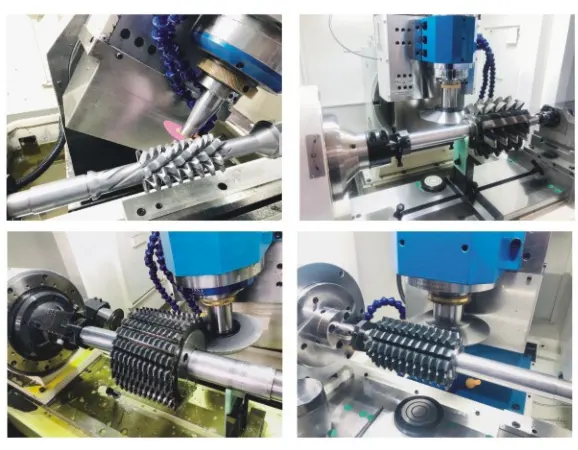

Working Principle of a Worm Grinding Machine

The worm grinding machine operates based on the principle of using the grinding particles on the grinding head to cut the worm surface, thereby acquiring the required worm thread. The precision of the worm grinding machine depends on the machine's structural design, the quality of the grinding head, and the machining process.

Applications of a Worm Thread Grinding Machine

Worm thread grinding machines are primarily used to manufacture worm drive devices and reducers. They are widely used in mechanical, metallurgical, chemical, and construction industries. Specific applications include:

1. Manufacturing Worms for Worm Drive Devices

The worm thread grinding machine can process worms with various precision requirements, meeting the usage requirements of the worm drive devices.

2. Manufacturing Worms for Reducers

The worm thread grinding machine can process worms with various precision requirements, meeting the usage requirements of the reducers.

3. Manufacturing Other Parts Requiring Worm Threads

The worm thread grinding machine can process worms with various precision requirements, meeting the usage requirements of parts such as worm pumps, worm oil pumps, and worm elevators.

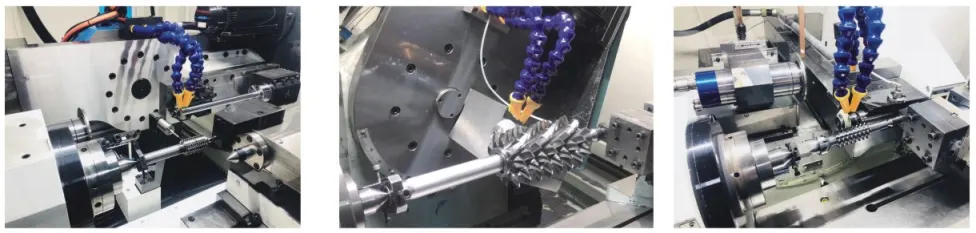

Why Choose Our Worm Grinding Machine?

We are a leading manufacturer of CNC machine tools and gear hobbing tools. Our company has a team of engineers and operators with extensive experience in gear hobbing and CNC equipment manufacturing. We offer excellent pre-sales and after-sales service, and we have the relevant intellectual property rights and numerous patented technologies. Our product designs are computer-optimized, and we use full CNC machining technology and a perfect quality control system. Our worm grinding machine is highly efficient and accurate, and it's been highly praised by users worldwide. We encourage you to explore this product and contact us for purchase. We guarantee excellent quality, competitive prices, effective supply, and excellent service.